|

REAL

COMMUNITY

Products

Online

FAQ

Feed Back

Back to HOME

|

1. Roots

Blower

1.

Q. What are

the major applications for Roots Blower?

A.

Usually the applications are as following:

(1) Industry wastewater treatment

(2) Domestic wastewater treatment

(3) Vacuum

(4) Dewatering in pulp&paper industry

(5) Dewatering in Dye industry

(6) Transport air

(7) Transport powder

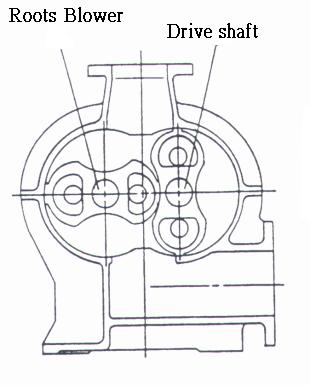

2. Q. What's the

mechanism for Roots Blower?

A. The

rotors rotate cause the air is absorbed from inlet and

compressed out to the outlet.

3. Q. What's the range

for air flow and pressure?

A. 1. Air flow(

m3/min)= 0.7- 400

2. Pressure( kg/cm2)= 0.1- 1.0

3. Vacuum( kg/cm2)= - 5000 - 0

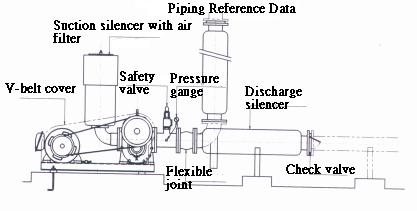

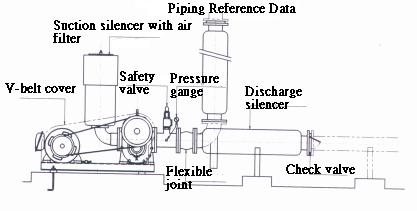

4. Q. What are

standard accessories for Roots Blower?

A. Suction

Silencer, Belt Guard, Reducer, Safety Valve, Check

Valve, Flexible Joint, Discharge Silencer, Motor

5. Q. What's material

for Roots Blower?

A. Casing:

FC25, Impeller: FC25, Drive shaft: S45C

6. Q. What's the

generally noise?

A. The

noise(dB) depend on RPM. The general is 75-85 dB.

7. Q. Why I feel the

insufficient blower during blower have run some time?

A. The

reason is stuffed filter. The remedy method is replace or clean the

filter.

8. Q. Why the motor

overload?

A. The

reason may be increased loss of pressure in the piping.

Or contact of impellers with the side covers. The remedy method is

1. Check the

difference of pressures between inlet and outlet.

2. Increase the side clearance.

9. Q. How to solve the

overheat problem?

A. The

blower overhead may be

1. excess lubricating oil in the gear case

2. Increased ratio of compression

3. Contact of the impellers with the side cover

The remedy method is

1. Check the oil level

2. Check the inhaling and discharging pressure

3. Increase the side clearance

10. Q. Why blower

occur the knocking sound?

A. The

reason perhaps is

1. Incorrect assembling

2. Abnormal increase in pressur

3. Damaged gear caused by overload or insufficient lubrication

The remedy method is

1. Reassemble

2. Check the cause of the increase

3. replace the pilot gear

e-mail:

webmaster@en-found.com

¡@

Enfound Enterprise Co.,Ltd. 2000 All Rights Reserved

|

Free

Newsletter for content

updated and more.....

Need Help?

Need help solving wastewater treatment or others problems? Are you

searching for equipment for your applications?

(Click here) Post message on forum for answer.

|